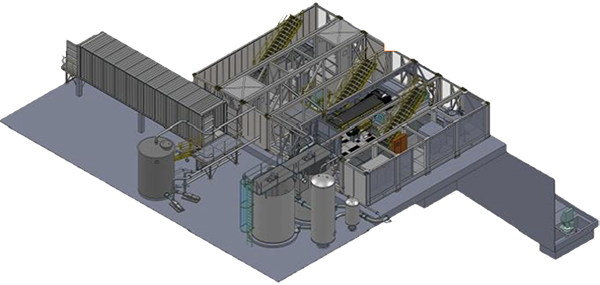

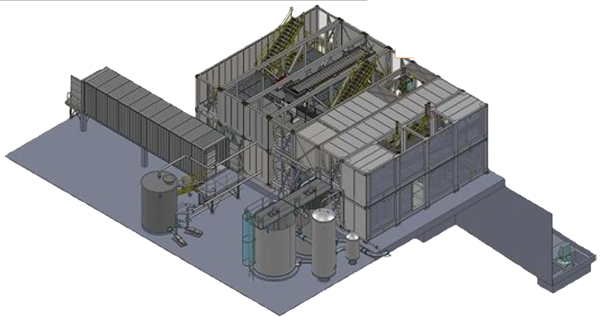

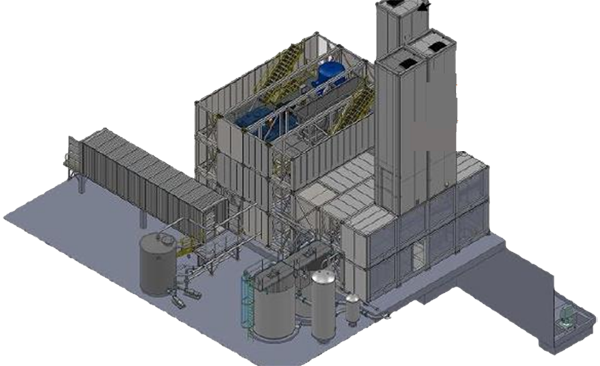

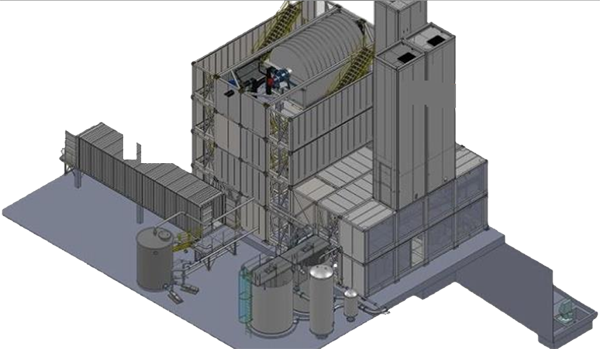

Fast-Track Conversion from Paste-Aggregate-Fill to continuous Paste-Fill (3,600 t/d)

Gold Mine (East Africa)

Situated in northwest Tanzania, this gold mine is in the Kahama district of the Shinyanga region, approximately 55 kilometers south of Lake Victoria and 150 kilometers southwest of the city of Mwanza.

This mine is a narrow-vein gold mine containing gold, silver, and copper mineralisation in sulphides. The mineralisation of the mine is associated with several steeply dipping veins. This gold mine commenced commercial production in 2001.

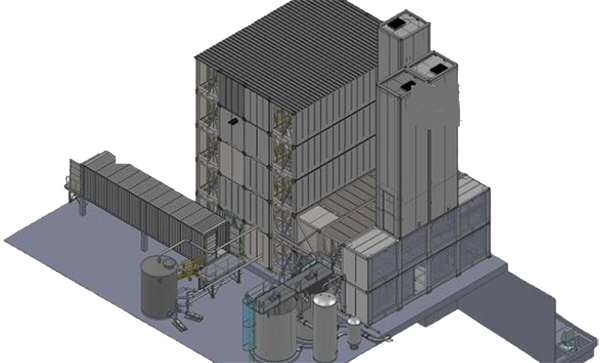

To avoid risks associated with blockage and downtime generated using aggregate, RMS converted the plant to a continuous paste tailings backfill system, replacing the original cemented paste aggregate fill (“PAF”) plant. RMS also retrofitted the existing plant to utilize only filter cake produced from dewatered mill tailings. The paste fill plant, commissioned in 2021, is now being expanded with a new, faster binder delivery.

The project was executed to transition the existing, old, worn backfill plant to one more suitable for the Life-of-Mine plan and to ensure that backfill could reach the new depths and extent of mining operations reliably and cost-effectively as further exploration continues.

This innovative project was successfully delivered despite the COVID-19 pandemic, and various supply-chain, personnel, and logistical challenges.

RMS worked together with the principals since the projects inception in June 2020, jointly delivering the turnaround plan, detailed engineering, and various testwork campaigns.

The pastefill plant is designed to process 155 dry tph of tailings filter cake, producing a total throughput of 109 m³/hr through a 200-mm nominal dia. pipeline at approx. 1m/s velocity of cemented paste(175mm slump). Upon recent commissioning of the upgraded cement silos and electrical/MCC systems, the pastefill plant handover has been completed and the project has reached and is maintaining target nameplate throughput.

The future implementation of a new paste pump will lower overall binder costs and increased operational flexibility of the system to flush quickly and effectively to eliminate underground reticulation blockages.

The motivation to transition towards a continuous pastefill system relied heavily on the needs of the mining system and optimized Underground Distribution System (UDS). Using the UDS as the starting point for design of this plant, an optimized backfill solution was engineered to deliver backfill to all parts of the mine at high productivity and lowest effective all-in cost per tonne of fill.

A primary goal of the project was to develop an engineering solution that had a strong understanding of the historical, current, and future mining operations as laid out in the Life-of-Mine Plan and exploration upside. By combining mining and process experience, the project has delivered an alternative solution that will provide incremental productivity to this gold mine, and maximum shareholder value.

Project Highlights

Brownfield modification of the structural, mechanical, platework and piping of the PAF plant;

Installation of a new continuous mixer designed for paste-fill applications;

Installation of new primary cement silos, compressors, controls, and ancillaries;

Installation of a new truck off-loading station;

Installation of a new binder screw conveyor and day silo;

Installation of valves, instrumentation, cabling and controls to support the process;

Installation of a new, containerized motor control center (“MCC”) and new PLC programming;

Installation of a new paste pump to distribute the paste to the underground mine.