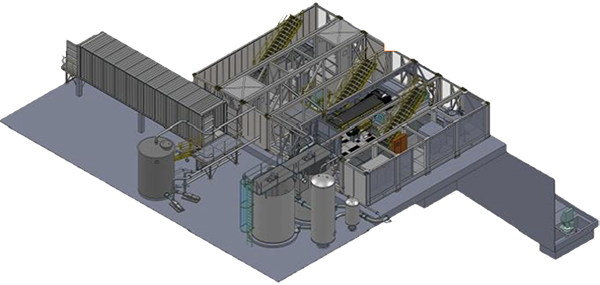

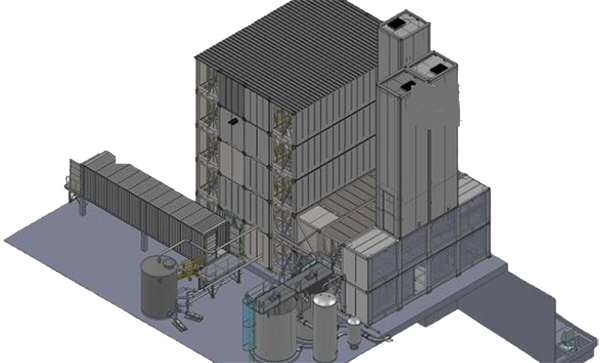

Unique Opportunities Create Unique Designs

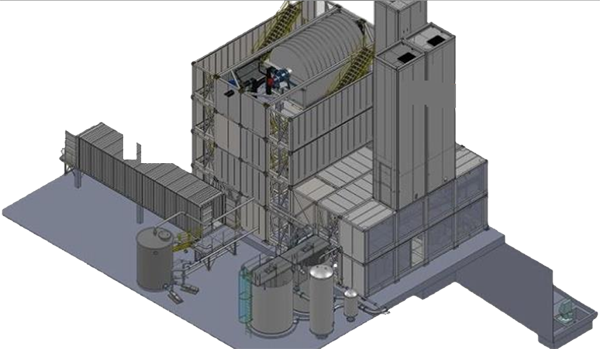

Modular design and prefabrication have the benefit of reducing time and complexity in engineering projects. Each module can be designed and assembled according to project and site requirements.

Engineered, prefabricated and modular construction solutions, benefit our clients by:

- Shortening installation and commissioning time

- Reducing the need for crane activity and heavy lifts

- Lowering the potential for Lost-Time-Injuries (LTI’s) and other Health & Safety concerns

- Accelerating project timelines

- Compacting and organized/staged lay-down areas

RMS has been reducing costs with engineered, modular solutions for mining operations around the globe. We are ready to assist our client to solve their most difficult mining challenges and provide improvements in safety, productivity, and efficiency.

Time, Cost & Safety Benefits

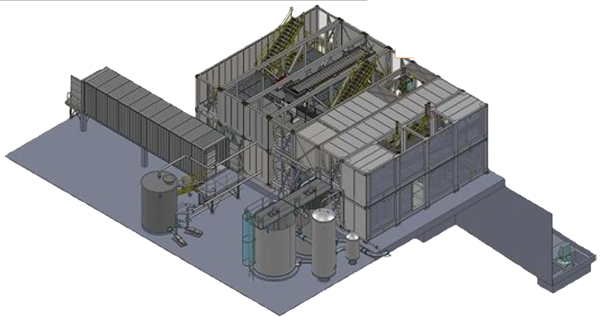

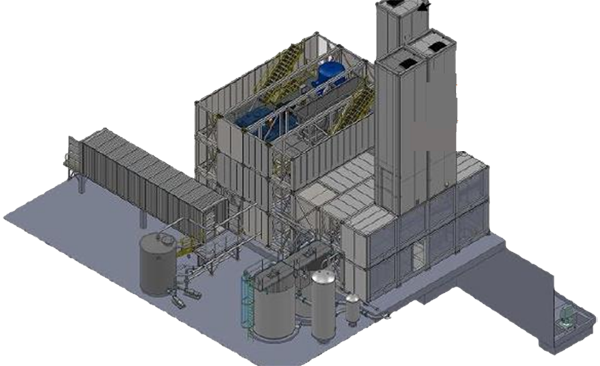

The open-frame modular design offers unique advantages as the majority of construction is completed off-site, offering time, cost, and safety benefits.

Custom Configuration

Open-frame design offers same horizontal and vertical work space as stick-built, with continuously improved designs to address maintenance and operational spatial requirements.

Save Time & Reduce Site, Labour and Equipment Costs

The modular construction method makes possible ultra-short site construction periods, with general assembly within a week and internal connections completed within a month.