Greenfield Paste Backfill EPC

Gold Mine (North America)

This brownfield gold mine is located in the gold belt near Val d’Or, Canada. Mining operations were restarted in 2021, after the successful completion of a pre-feasibility study conducted by RMS.

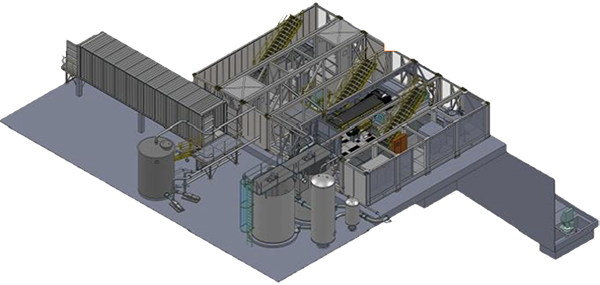

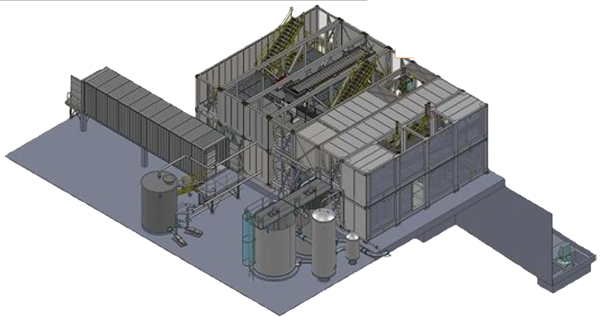

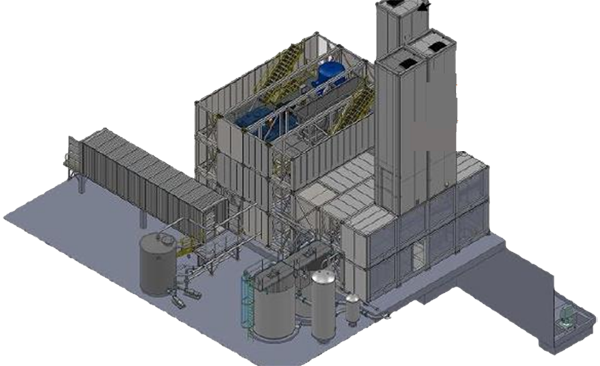

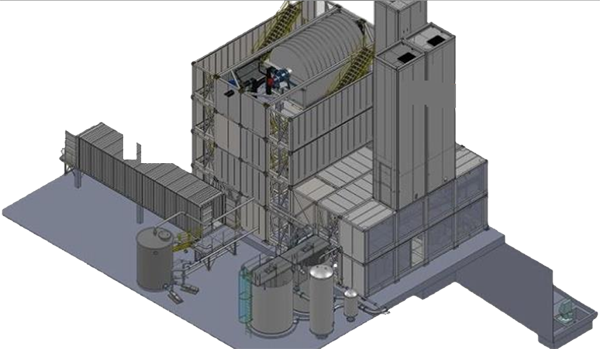

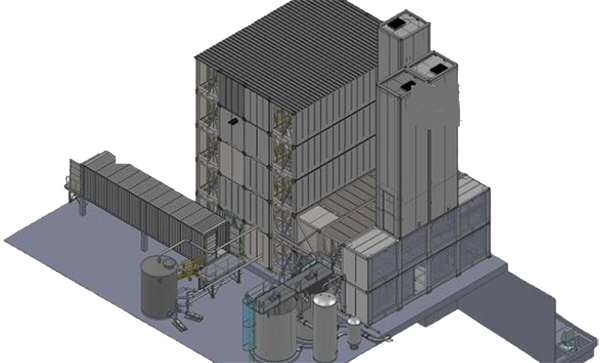

By providing passive support for underground mining operations and by reducing the footprint of the mine's tailings and increasing safety and stability of underground workings, RMS facilitated the construction of a turnkey Engineering, Procurement and Construction (EPC) Tailings and Backfill Plant.

The project's scope of work includes the construction of a thickener, tailings and backfill plant, a 2km dual walled surface disposal pipeline, and a 6” underground distribution system. The plant is a 60m³/h (80tph) continuous paste backfill plant with the primary technologies being a high compression thickener (HCT), a single vacuum disc filter, and a continuous twin shift mixer. The plant replaced an existing hydraulic backfill plant as paste technology allowed for quicker turnaround of the stopes required to meet the desired mine throughput and improved water management.

Much like a Swiss army knife, this plant was designed to be multi-functional. Not only serving paste backfill, but also converting the tailings facility to thickened tailings disposal, paste disposal to historical underground voids, as well as enabling filtered tailings disposal. This was done by the inclusion of a reversing conveyor and a live bottom truck load-out bin. This multi-functional design allowed the project to eliminate the need for a pressure filter plant and produced significant savings from preventing the expansion of the tailings dam.

The versatility of this plant also ‘future-proofed’ the mining site by allowing for more tailings within the existing storage facility footprint.

Project Highlights

Throughput – 80 tph backfill, 65 tph tailings disposal

Commodity – Gold Tailings

Project Stage – Execution (EPC)

Primary Technologies

High Compression Thickener (HCT)

Vacuum Disc Filtration

Continuous Twin Shaft Mixing

Continuous Binder Mass Flowmeter

Tailings SG – 2.9

Paste Density – 70 to 72w/w%

Material PSD

% Passing 20 micron - 55

P30 – 8.8 micron

P80 – 54 micron